During the Kickstarter campaign for the Leviathan, DreamForge offered up a free set of alternative exhaust parts for anyone pledging for the Leviathan itself. The original parts were a little too gothic In my opinion, looking like giant braziers straight out of the Warhammer milieu. The alternative parts on the other hand have a sleeker and more stream-lined look to them.

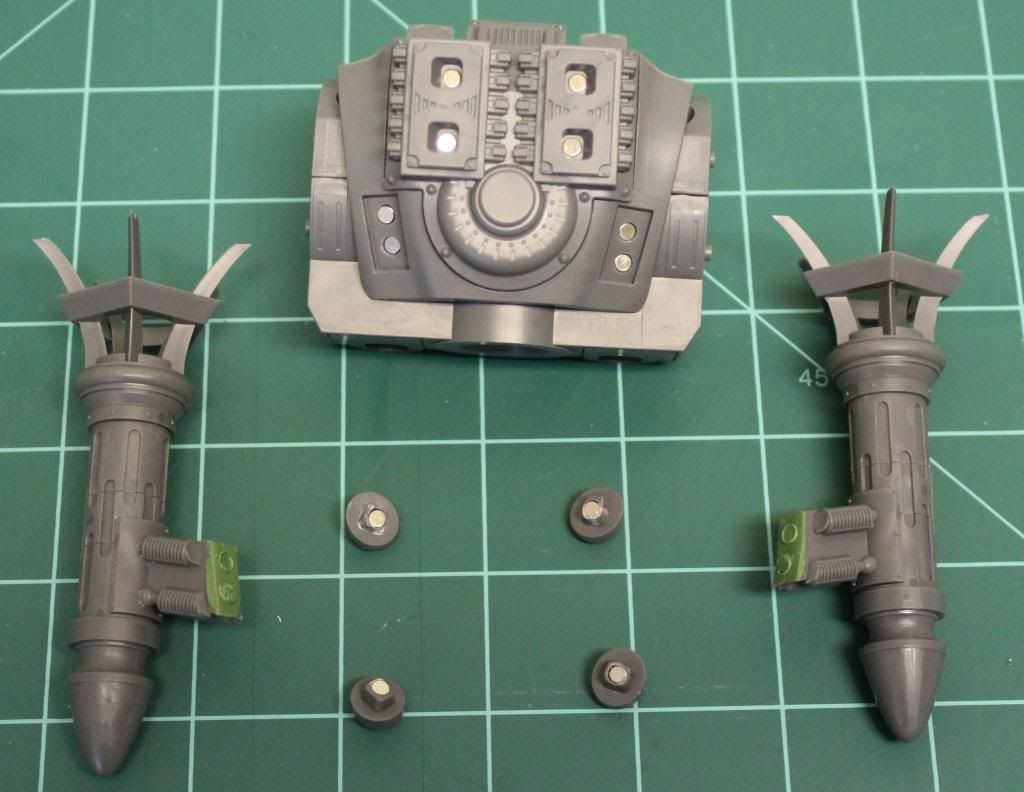

After mulling over the situation for a while I decided to use both, with a set of magnets for swapping back and forth. The original kit parts are rather beefy so it took two magnets in the slot before I felt that it would hold fast, and then two opposing magnets in the exhaust part itself. I am using 1/8" long and 1/8" diameter cylindrical, rare earth magnets on the parts. Unfortunately I was off on my drilling slightly and the magnets didn't quite line up true. As you can see by the photos I had to add a little green epoxy stuff putty to get everything to fit right.

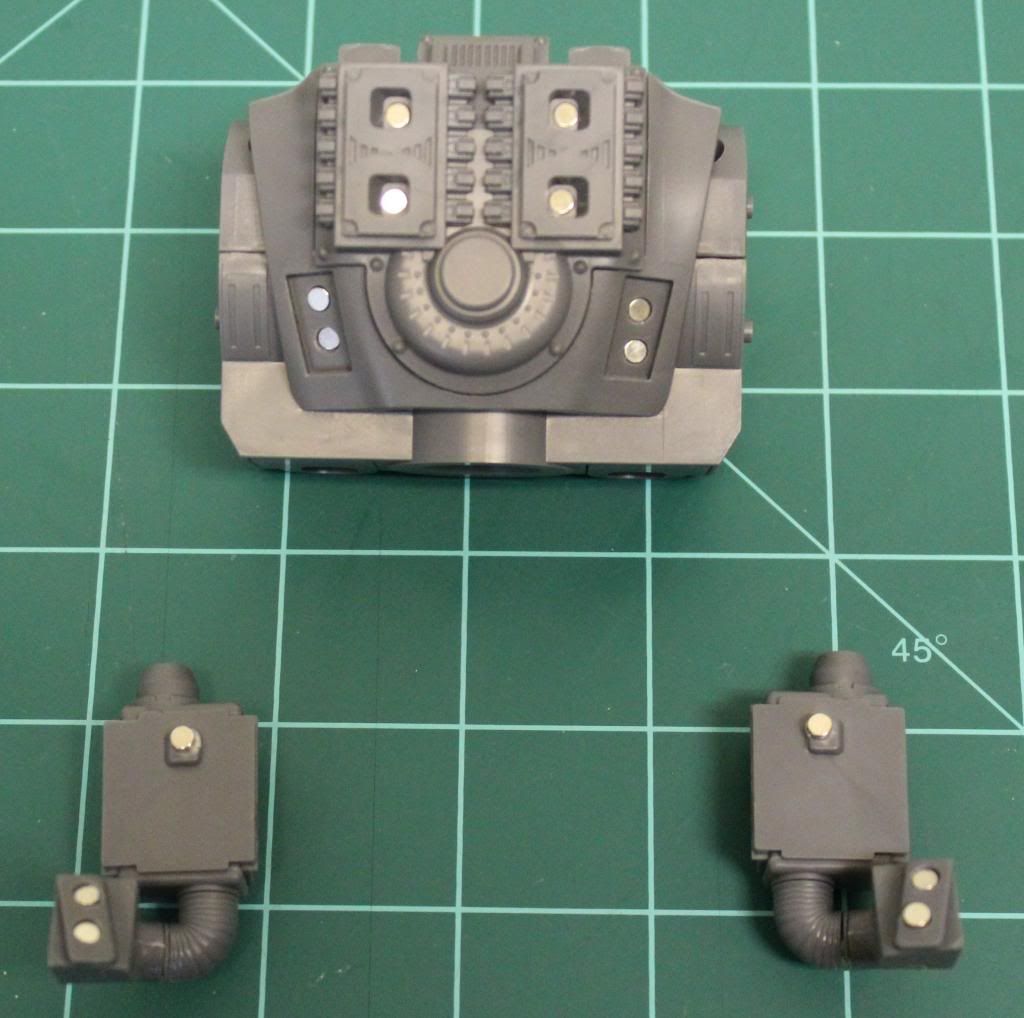

There are also four small parts that fit on the back of the engine that would have been in the way of the alternate parts. I had to magnetize them as well.

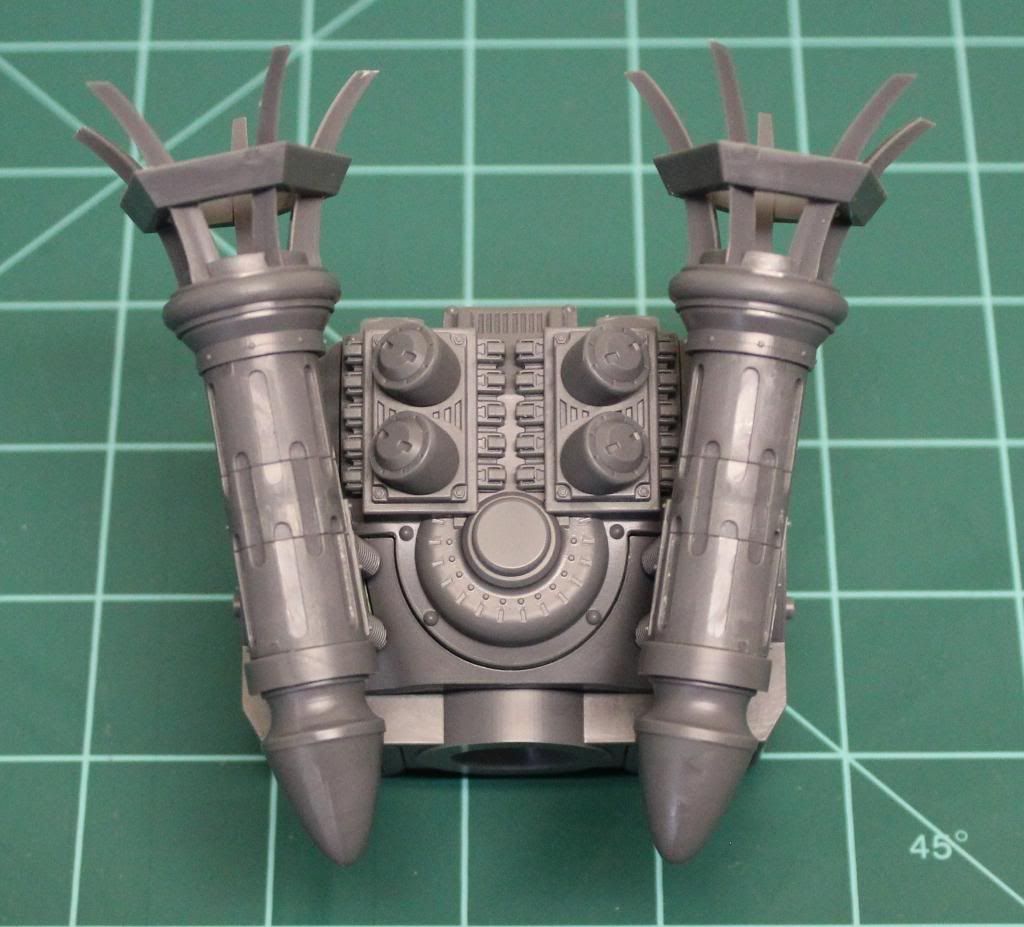

Next up were the alternate parts, listed from DreamForge as "Leviathan Capacitor Cooler". What I gather from the small amount of Iron Core background that has surfaced is that the exhaust stacks are intended, to vent excess heat when the Leviathan makes extended attacks or hard maneuvers, similar to the heat sinks in Battletech. The alternative parts are supposedly more efficient at venting that heat. Either way, I like the look of the alternative set much more. As you can see, I've magnetized these as well utilizing the same sized magnets in the most of the same locations. These parts are lighter and fit closer to the torso, so I didn't need all four.

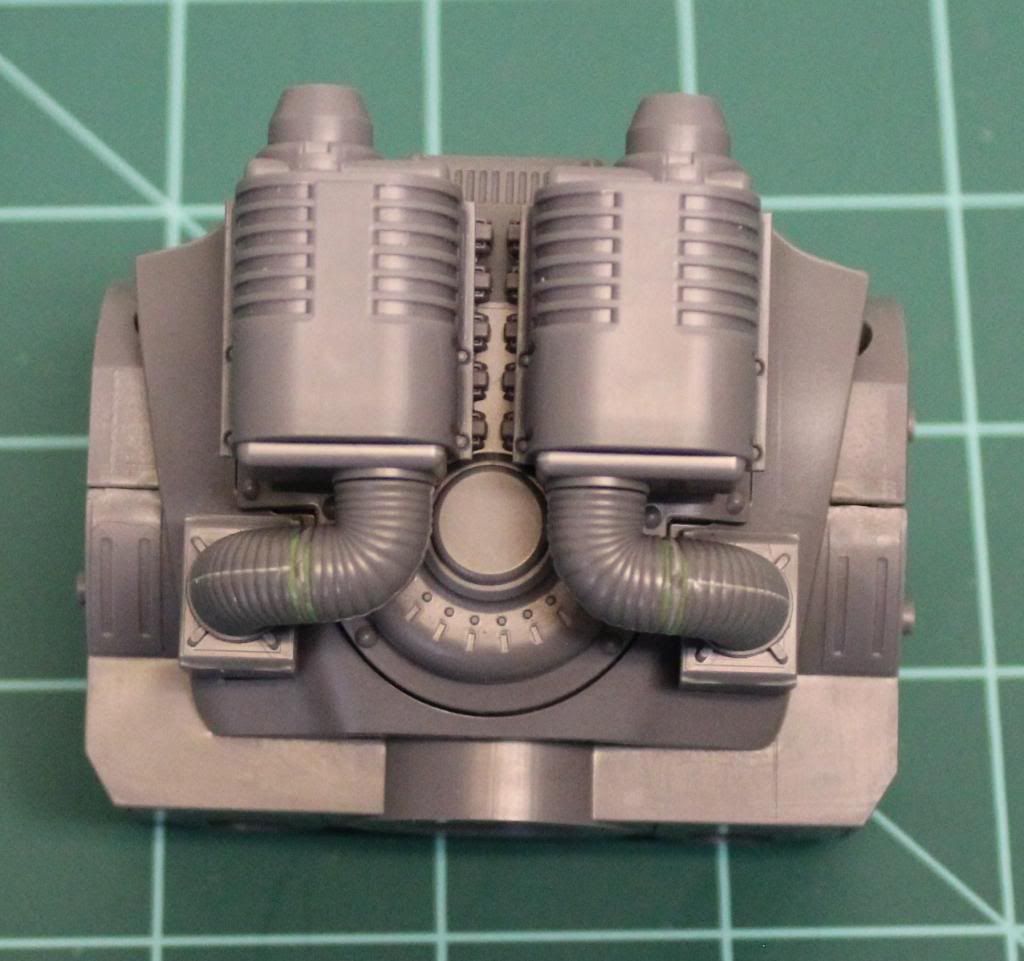

I was a little more careful with my drilling this time and the opposing magnets lined up much better this time. The hoses that connected the coolers to the torso did not fit quite right, so I needed to green stuff the joints a little bit as well.

One dissapointing thing that working on the torso has shown me is that I will have to give up the idea of adding a cockpit. The way the chest, face and roof parts all fit together, it will be nearly impossible to make the face part removable to see the cockpit without some major surgery. Oh well, that will cut some time off the schedule and keep the project rolling. I probably would have spent a week or two scratch-building a cockpit and converting a pilot to fit.

No comments:

Post a Comment